Steam Jacketed Valves

Valve Thermal Management Solutions

Many chemical and processing facilities operate under strict temperature control requirements. When a liquid or liquefied product becomes thermally unstable, the consequences can be costly—production delays, unplanned downtime, and even equipment damage. That’s why reliable thermal control isn’t optional—it’s essential.

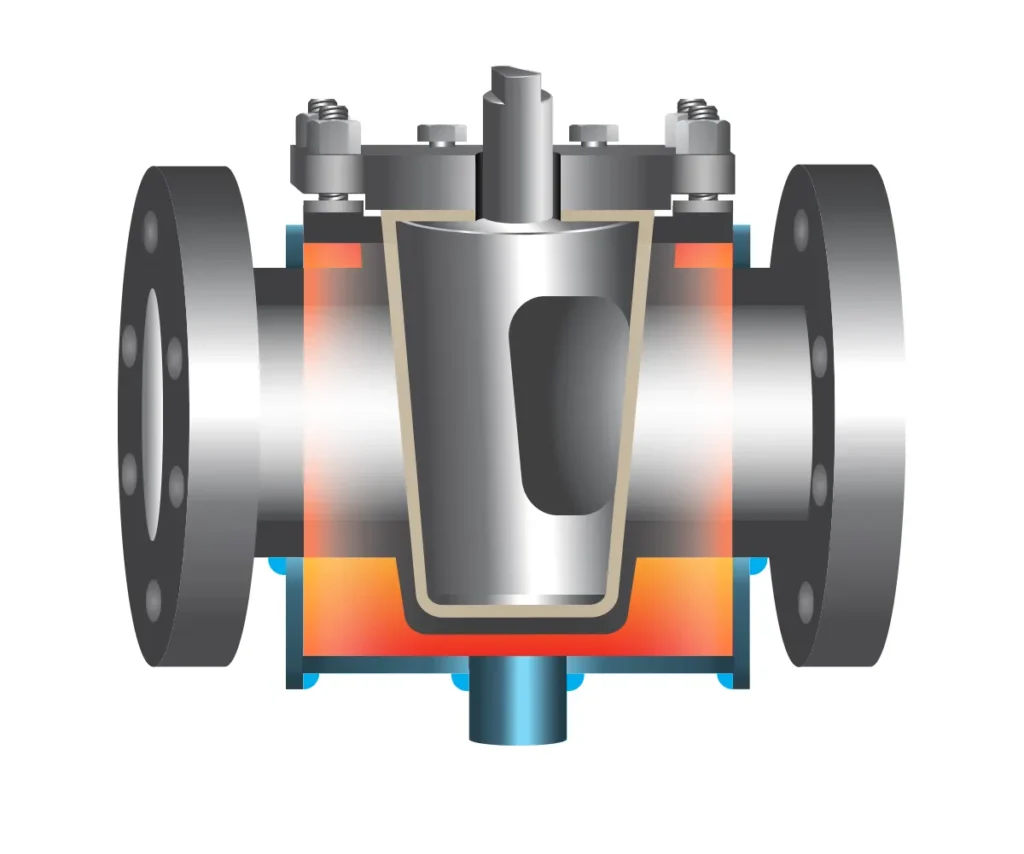

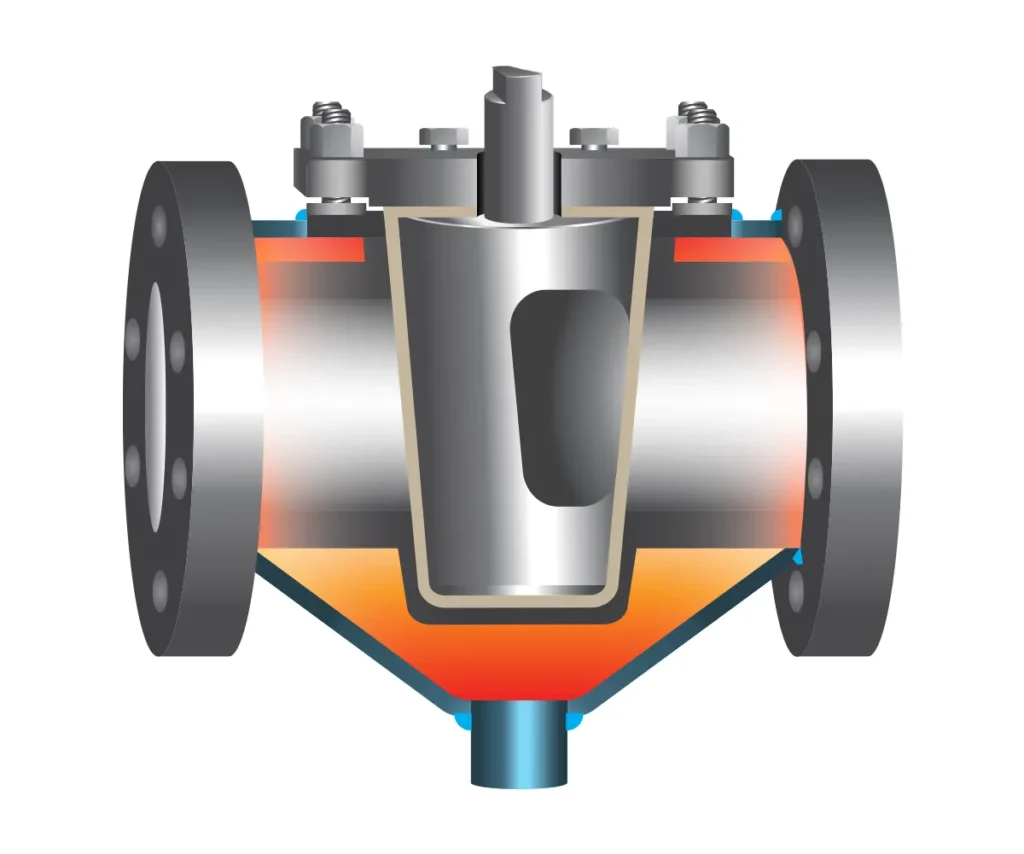

At the heart of effective thermal management is proper thermal migration. Our jacketed systems are engineered to ensure smooth, unobstructed flow of the thermal fluid, allowing it to perform efficiently and consistently. By maintaining sufficient annular space between the exterior of the jacketed valve and the inner wall of the jacket, we eliminate temperature inconsistencies and hot or cold spots. The result is a highly stable, “temperature-predictable” system based on a proven Double Pipe Thermal Exchange System design.

While standard drawings and dimensions can meet basic requirements, many applications demand more. That’s where Reliant Valve stands apart. Since 1998, we have specialized in custom jacketed valve solutions—engineering products that go beyond the “standard” to meet the real-world needs of our customers. When no template exists, we rely on experience, innovation, and proven fabrication techniques to deliver dependable results.

We offer three standard fabricated valve jacket designs:

Every design can be customized to your application. Options include jacket material selection, steam port quantity and configuration, bonnet jacketing, custom take-out dimensions, and more. Whatever your process demands, Reliant Valve delivers a jacketed valve solution you can rely on—engineered for performance, durability, and peace of mind.

Steam Jacketed Valve

Configurations

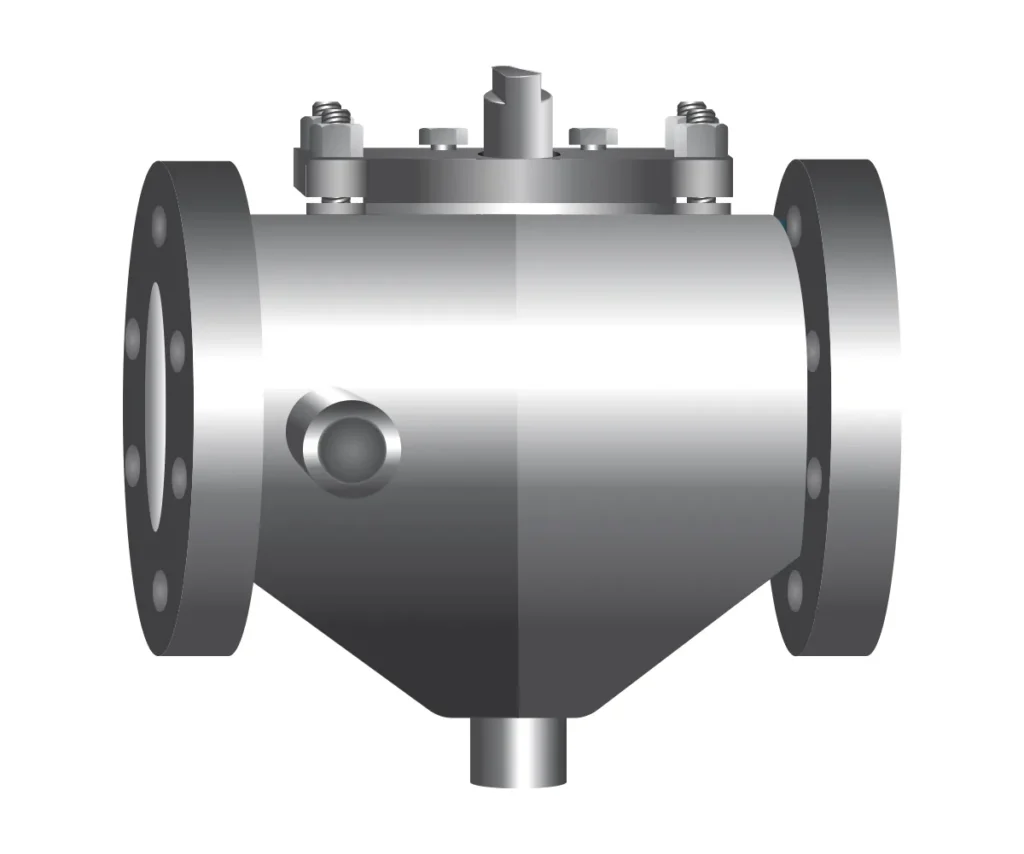

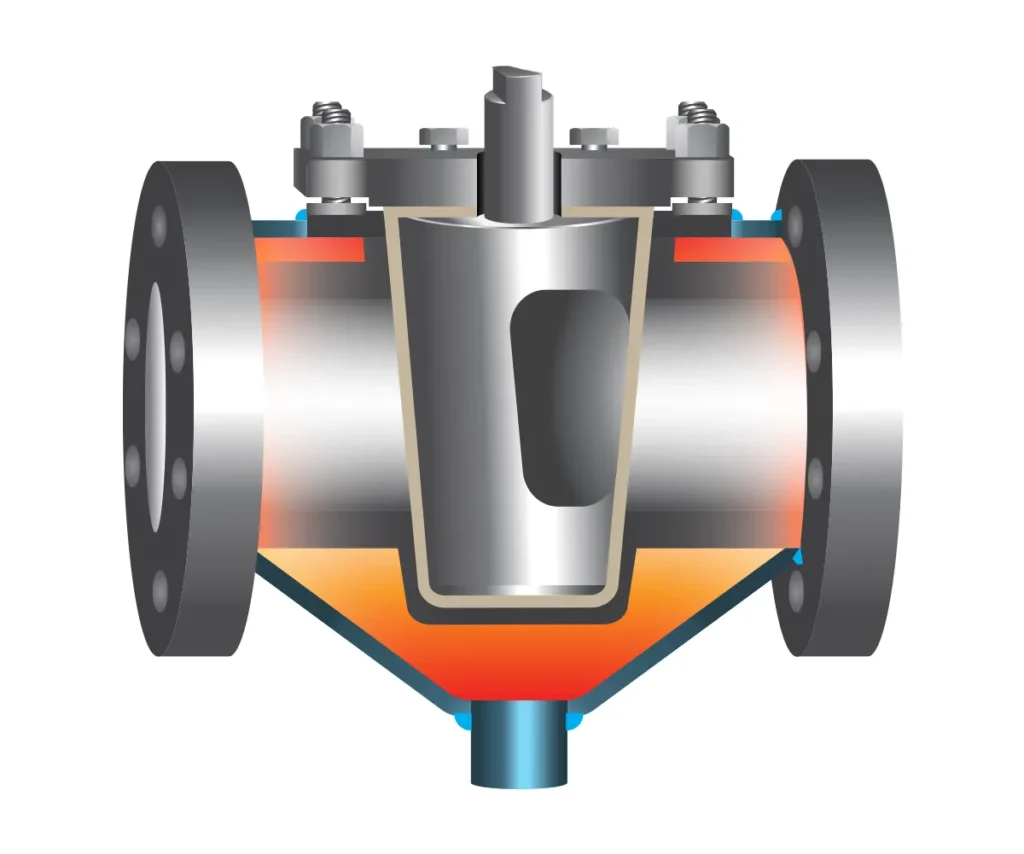

Partial Jacketed Valve

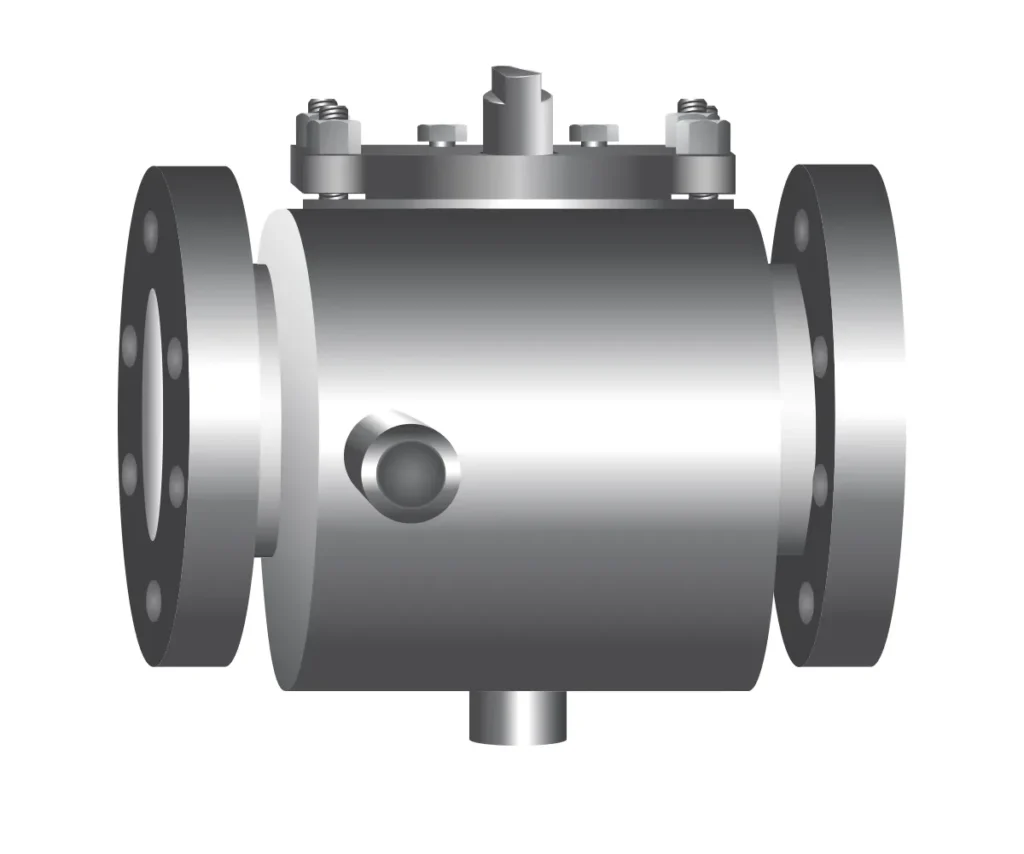

Type "A" - Standard Flange

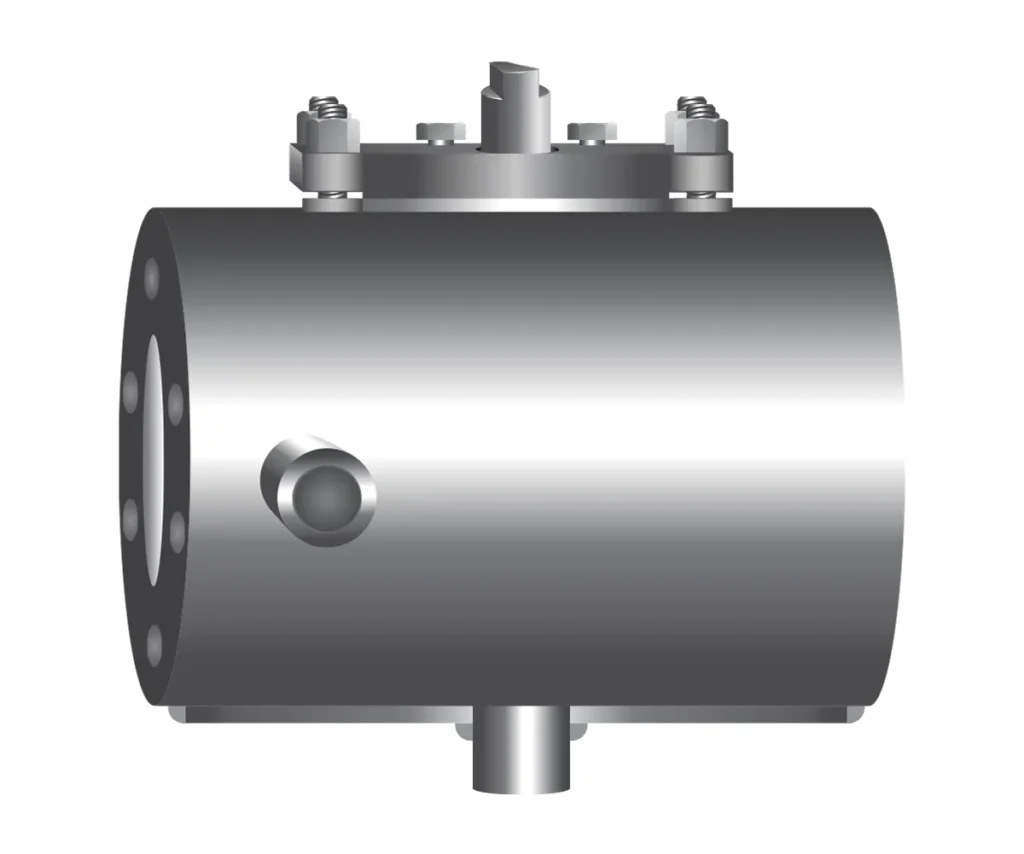

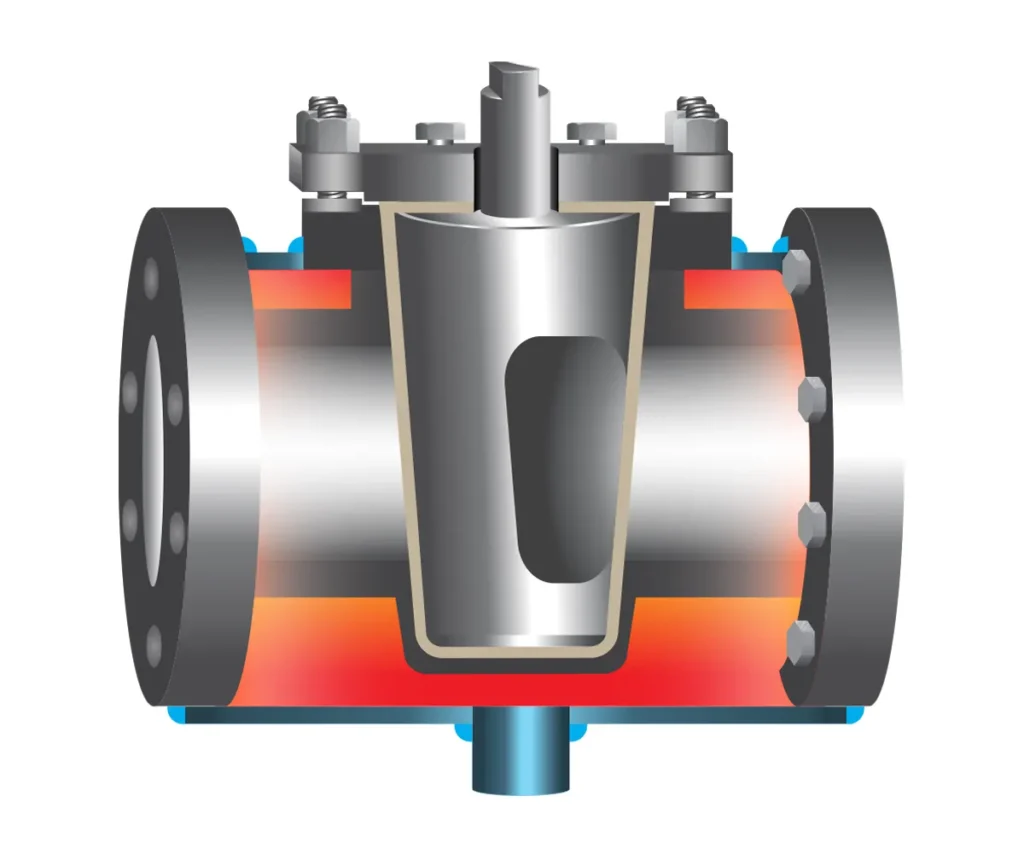

Full Jacketed Valve

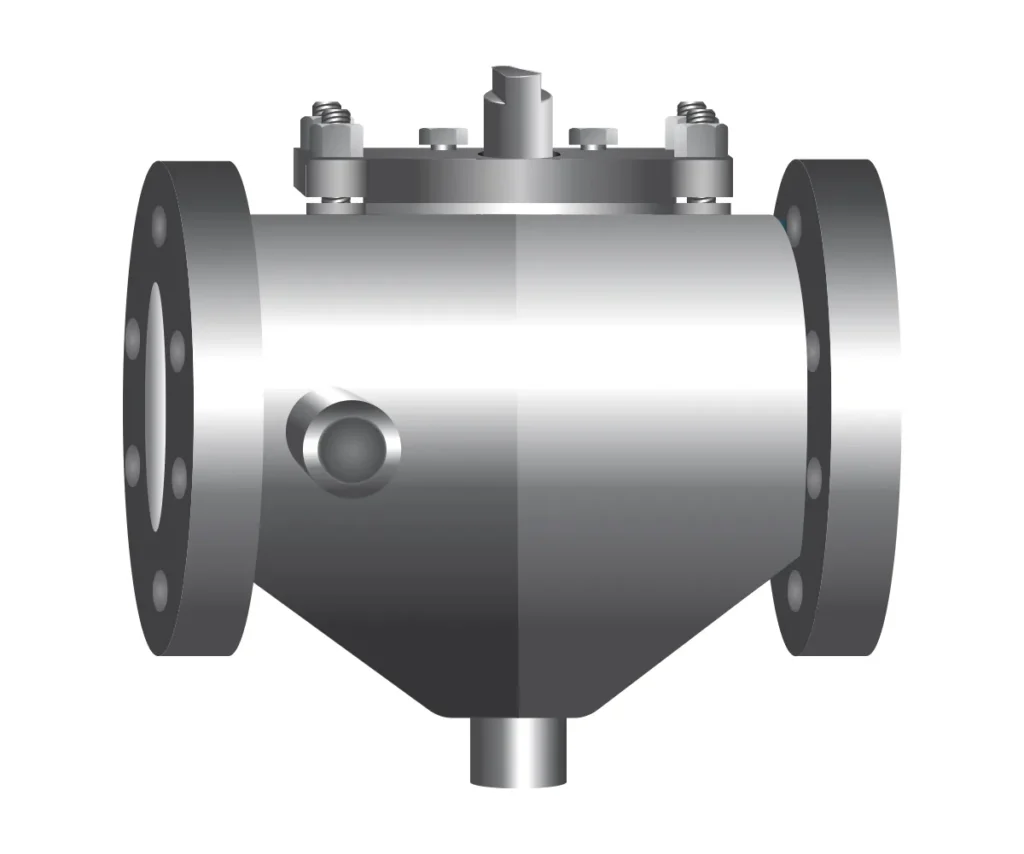

Type "B" - Oversized Flange

Full Jacketed Valve

Type "C" - Standard Flange

(Line Size Jacket)

Steam Jacketed Valve

Configurations

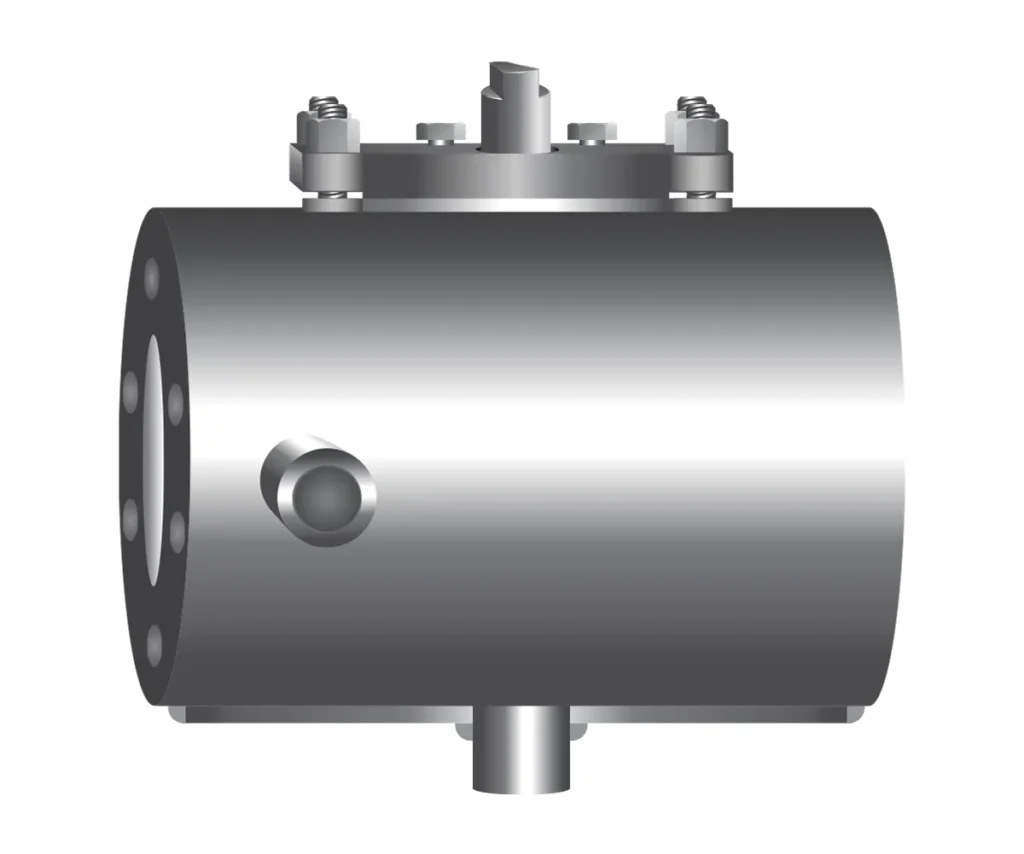

Partial Jacketed Valve

Type "A" - Standard Flange

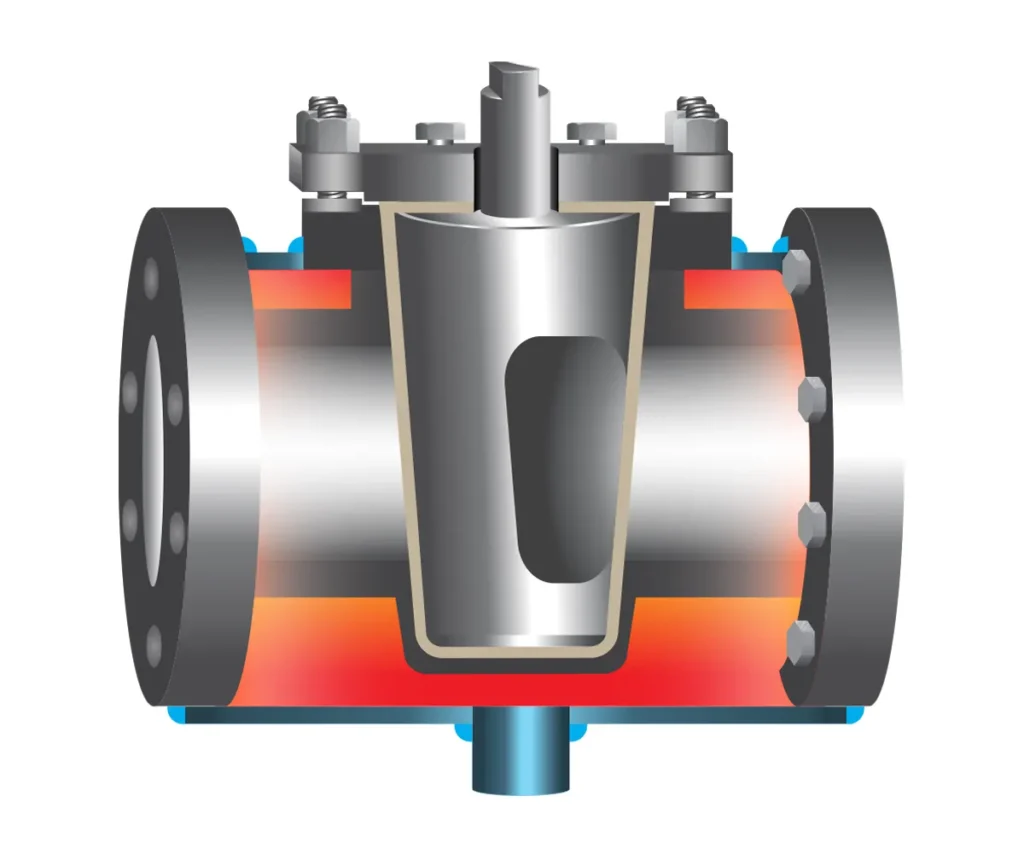

Full Jacketed Valve

Type "B" - Oversized Flange

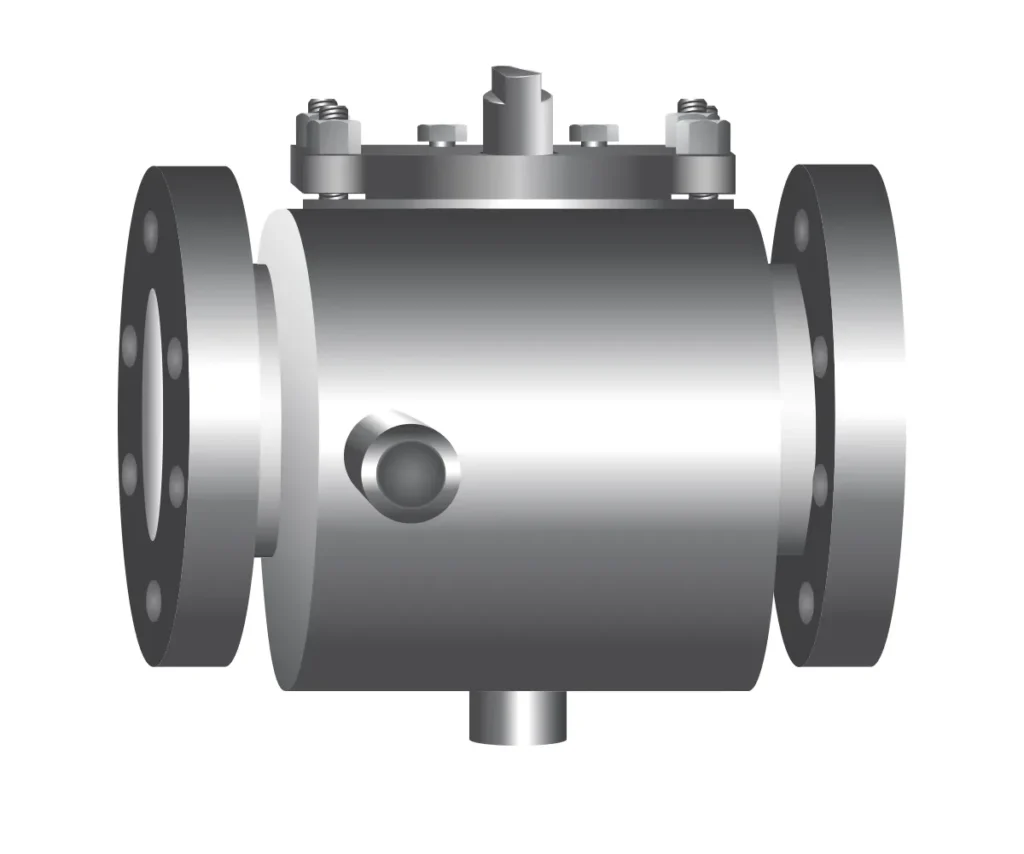

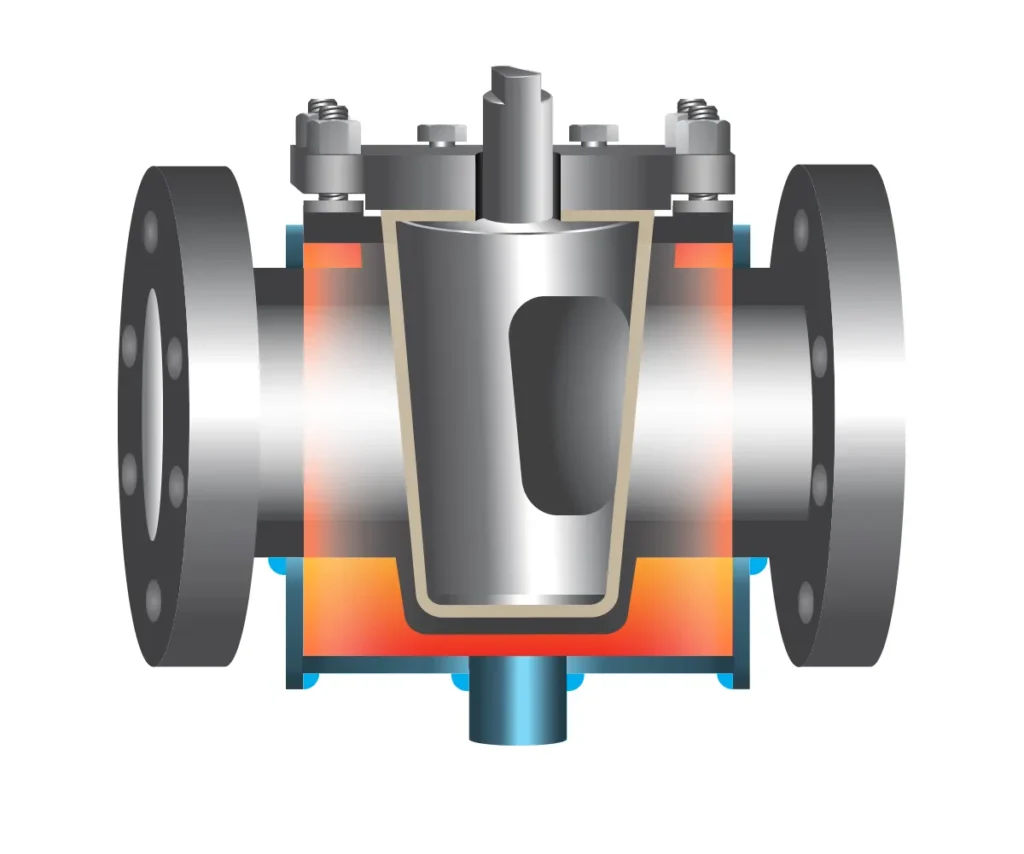

Full Jacketed Valve

Type "C" - Standard Flange

(Line Size Jacket)

In-House

Fabricated Valve Jackets

Durco

3x2x3 Plug Valve

Full Jacket

Warren

Full Port Ball Valve

Partial Jacket

FluoroSeal

Plug Valve

Partial Jacket

Xomox

Plug Valve

Line Sized Full Jacket

ASME Boiler & Pressure Vessel Code Certified

As demand for jacketed valves has increased over the past several decades, we have continually expanded our capabilities to meet the evolving needs of our customers. Our fully equipped fabrication facility features comprehensive machining and welding resources, allowing us to deliver precision-engineered solutions for even the most demanding applications.

All welding is performed by ASME Boiler & Pressure Vessel Code–certified welders, ensuring the highest levels of quality, safety, and compliance. We fabricate both full and partial weld-on jackets across a wide range of valve designs, providing flexibility to match your specific process requirements.

Material selection is tailored to each application. In addition to carbon steel and stainless steel, we offer high-performance nickel-based alloys for environments that demand enhanced corrosion resistance, temperature stability, or chemical compatibility.

Every valve is thoroughly tested following fabrication. Jacket integrity is verified through hydrostatic testing in accordance with ASME B31.1, and after final assembly, the process side of the valve is tested to the API 598 standard. This rigorous testing protocol ensures dependable performance, long service life, and confidence in every valve we deliver.

Questions & Answers

What is a jacketed valve?

A jacketed valve is an industrial valve designed with a jacket, or outer shell, that allows a thermal medium to circulate around the external body of the valve. With precise thermal control, it helps prevent viscosity changes, solidification, and product degradation.

When is a steam jacketed valve required instead of a standard valve?

Jacketed valves are required when the process media can become too viscous or solidify at operating temperature. Common applications include sulfur, asphalt, resins, heavy oils, adhesives, and pharmaceuticals.

How many types of steam jacketed valves are there?

There are three types of steam-jacketed valves:

1. Type “A” – Partial Jacket with Standard Flanges

2. Type “B” – Full Coverage Jacket with Oversize Flanges

3. Type “C” – Full Jacket with Standard Flanges (Line Size Jacketing)

4. Type “D” – Any of the Above Jacketed Valves (Only Shorter End-to-End)

Are jacketed valves used in both cold and hot services?

Yes, jacketed valves in a heated process are used to keep products like heavy oils and sulfur flowing through the system. In cold service, jacketed valves are used to maintain a low temperature in the manufacturing of certain acids, pharmaceuticals, adhesives, food, and beverages.

What size thermal ports are available?

THERMAL PORTS: ½”–3″ valves: ½” FNPT, 4″–6″ valves: ¾” FNPT, 8″+ valves: 1″ FNPT

Bonnet Jackets for Gate, Globe & Swing Check valves; flanged and other port types available.

What heating and cooling fluids are used in jacketed valves?

While steam is the most common heating medium, other thermal fluids, such as hot oil, are also used. For cooling a jacketed process, cold water or chilled glycol are the most common fluids used to keep the system in a precise thermal state.

What types of valves can be jacketed?

Most commodity valves can be jacketed, including:

- Plug Valves

- Ball Valves

- Gate Valves

- Globe Valves

- Check Valves

- Sample Valves

- Diverter and Multiport Valves

- Control Valves

Configurations: Flanged End, Butt-Weld End, SW or TH End. Bonnet Jacket are available too.

The optimal valve type depends on the service and design requirements, shutoff requirements, and the characteristics of the process media.

When your process can’t afford a shutdown, talk to the steam jacketed valve experts.

Contact us now!